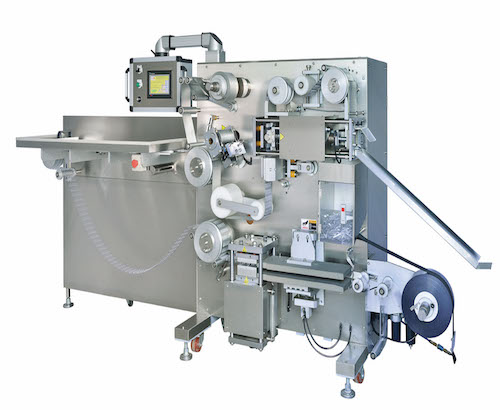

High Efficiency Tablet Blister Packaging Machine

Our B2 high efficiency blister packaging machine by UTOC utilises the latest blister forming and sealing technology which offers customer extreme ease of use and set up with high output efficiency enable the B2 to run at speeds of up to 40 cycles per minute.

The B2 are suitable for blister packaging of medicinal tablets, sugar coated capsule, film coated hard or soft gelatine capsules.

- Features

- Specifications

- Brochure Download

- Demo Video

- Continuous roll feeding for low noise and maintenance.

- Cross perforation of the blister cards.

- Contact heating of PVC film allows low temperature and uniform blister formation at various machine speeds.

- No waste / no trimming card cutting feature saves material.

- Safety indicator lights facilitate trouble shooting.

- Size changes easily accomplished in less than 20 minutes making this a truly versatile machine.

- P.I.D. temperature controls for precise blister forming, sealing, perforation and coding.

- Product feed track allows for manual product feeding if desirable.

- Includes blister counting controls.

- Can easily be changed over to handle tables, capsules and soft gel capsules.

- Ec speed variable main-motor.

Options

- Blister Size Change

- Vibrating Tablet/Capsule Feeder

- Automatic Tablet/Capsule Feeder

- Cooling Chiller

| Model | B2 |

|---|---|

| Machine Dimension | 3200mm x 1650mm x 1050mm (H) |

| Max Output | Up to 40 cycles per min |

| Max PVC Web Roll Width | 155mm |

| Max PVC Thickness | 350 microns |

| Max Forming Area | 140mm x 78mm |

| Max Blister Forming Depth | 12mm |

| Power | 415V – 3 Phase – 50Hz |

| Power Consumption | 4.2Kw |

| Air Requirements | 7cfm @ 70psi |

Products

High Efficiency Tablet Blister Packaging Machine

Our B2 high efficiency blister packaging machine by UTOC utilises the latest blister forming and sealing technology which offers customer extreme ease of use and set up with high output efficiency enable the B2 to run at speeds of up to 40 cycles per minute.

The B2 are suitable for blister packaging of medicinal tablets, sugar coated capsule, film coated hard or soft gelatine capsules.

- Features

- Specifications

- Brochure Download

- Demo Video

- Continuous roll feeding for low noise and maintenance.

- Cross perforation of the blister cards.

- Contact heating of PVC film allows low temperature and uniform blister formation at various machine speeds.

- No waste / no trimming card cutting feature saves material.

- Safety indicator lights facilitate trouble shooting.

- Size changes easily accomplished in less than 20 minutes making this a truly versatile machine.

- P.I.D. temperature controls for precise blister forming, sealing, perforation and coding.

- Product feed track allows for manual product feeding if desirable.

- Includes blister counting controls.

- Can easily be changed over to handle tables, capsules and soft gel capsules.

- Ec speed variable main-motor.

Options

- Blister Size Change

- Vibrating Tablet/Capsule Feeder

- Automatic Tablet/Capsule Feeder

- Cooling Chiller

| Model | B2 |

|---|---|

| Machine Dimension | 3200mm x 1650mm x 1050mm (H) |

| Max Output | Up to 40 cycles per min |

| Max PVC Web Roll Width | 155mm |

| Max PVC Thickness | 350 microns |

| Max Forming Area | 140mm x 78mm |

| Max Blister Forming Depth | 12mm |

| Power | 415V – 3 Phase – 50Hz |

| Power Consumption | 4.2Kw |

| Air Requirements | 7cfm @ 70psi |

Products

Contact

Awards

One comment

Pingback: PACSEAL Packaging Machines | UTOC (SINGAPORE) PTE LTD

Comments are closed.