What is an Ink Jet Coder?

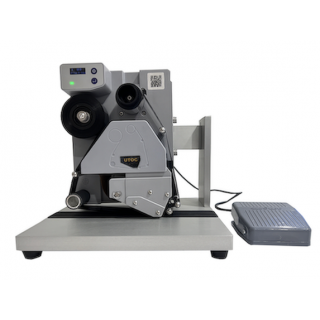

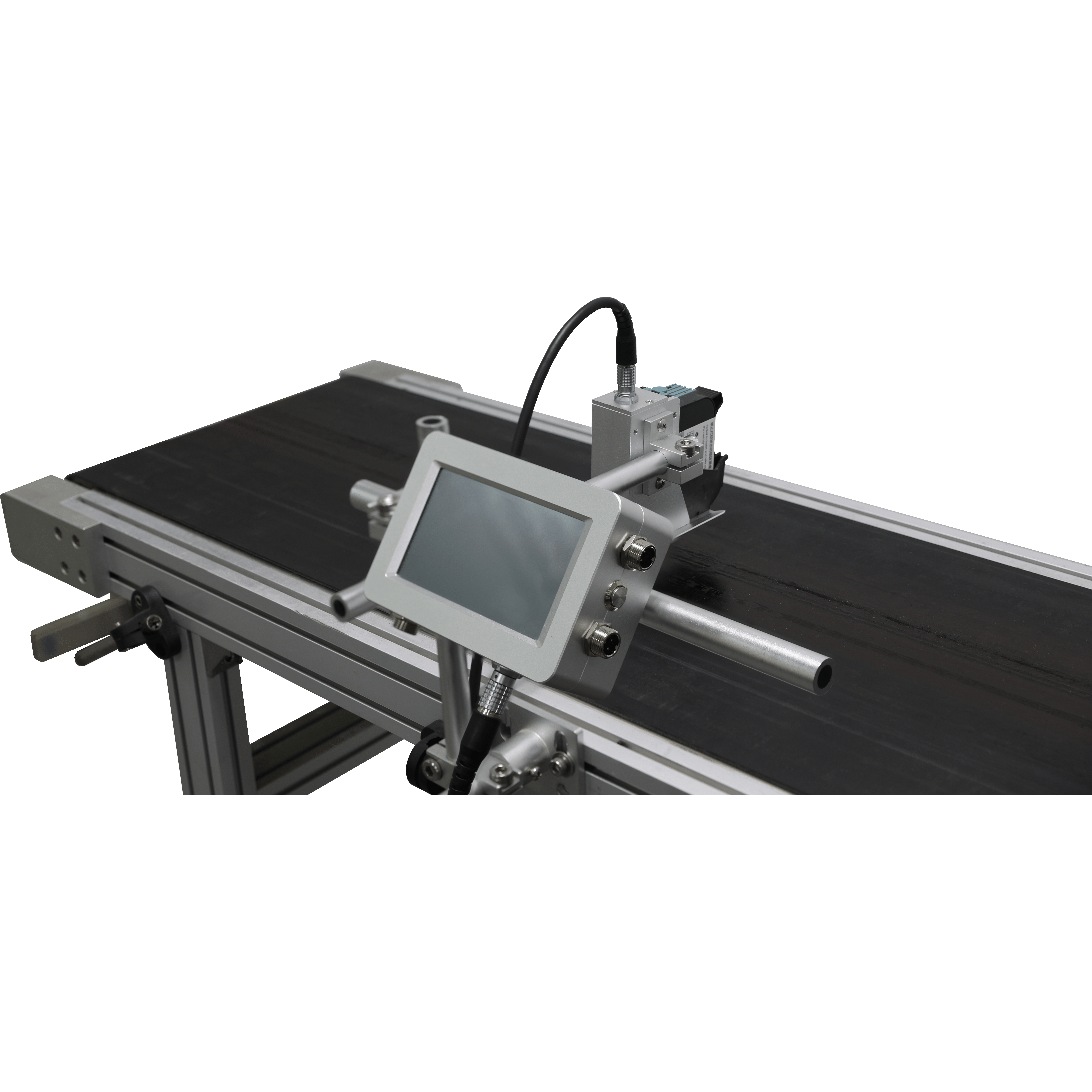

UTOC‘s Inkjet coders, also known as continuous inkjet printers, are machines used for marking and coding products with text, logos, or graphics. These printers use ink droplets to create high-quality, permanent marks on a variety of surfaces including paper, plastic, metal, and more.

UTOC offers a range of inkjet coders to fit your specific needs, from entry-level machines to advanced models capable of handling high-speed production lines. Contact us today to learn more about how our inkjet coders can help improve your product labeling and coding process.

How Ink Jet Coders Can Benefit Your Business: A Guide

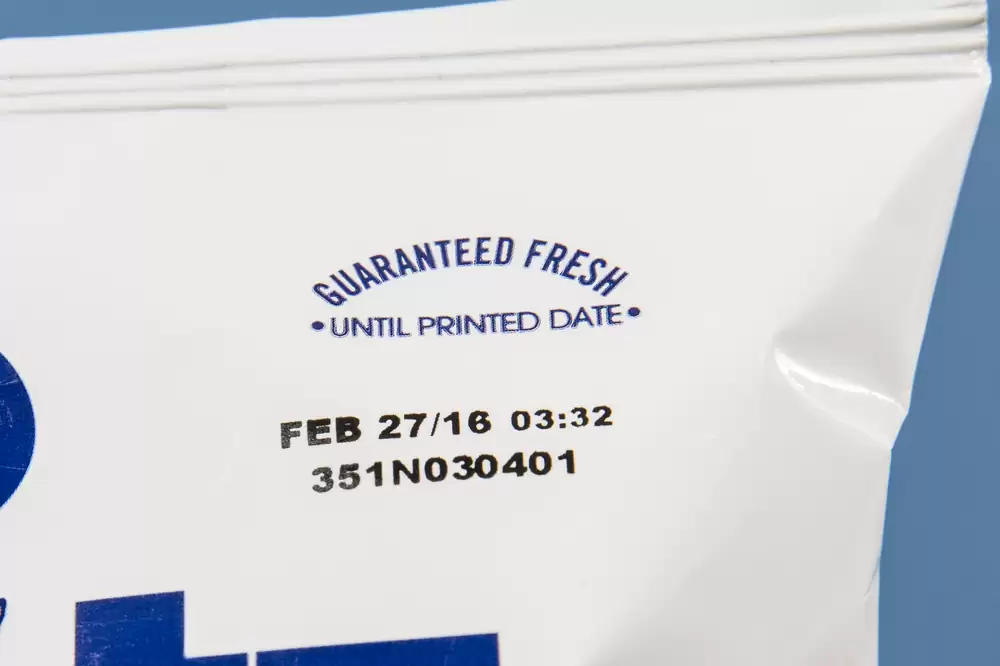

Inkjet coders are a versatile and efficient solution for printing high-quality codes, dates, and batch numbers on products. By using an inkjet coder, companies can ensure that their products are accurately labeled and comply with industry standards while improving efficiency and reducing costs.

One of the key benefits of using an inkjet coder is its ability to handle a wide range of printing materials and surfaces, including plastics, metals, and glass. This makes it an ideal solution for companies in a variety of industries, from food and beverage to pharmaceuticals and cosmetics. Inkjet coders are also easy to operate, with user-friendly software and intuitive interfaces that employees can quickly master.

In addition, inkjet coders are highly reliable and require minimal maintenance, reducing downtime and ensuring that production lines stay up and running. By investing in an inkjet coder, companies can not only improve their product labeling and compliance but also increase productivity and profitability in the long term.

Streamline Your Process with Our Inkjet Coders Today!

Contact

Awards